Semiconductor

3M brings precision, performance and efficiency to your semiconductor manufacturing process.

-

If you are involved in semiconductor manufacturing and handling, 3M Singapore has the solutions to help. Our expertise in areas like microreplication, nanotechnology, and moulding provide solutions which help enable the uniformity, cleanliness and precision your industry's processes demand.

For more than 50 years, 3M has been providing a wide range of materials to get you from start to finish in your process. This includes everything from materials used in etching and deposition, chemical mechanical planarization (CMP) and surface finishing materials for wafer processing, fluids for thermal management, tape and reel for chip transport and materials for wafer doping and ion implantation.

And when you partner with 3M, you have global support. Our technicians are there to help in key locations around the world.

CMP solutions

-

3M™ Trizact™ CMP Pads are designed to deliver predictable, stable, and consistent performance to your CMP process, leading to improved efficiency, reduced erosion, and increased yield. 3M's know-how in moulding, surface modification and microreplication enables the creation of this innovative pad that meets the demands of advanced node CMP processes.

-

3M Pad Conditioners for CMP provide consistent performance for current and advanced technology node chemical mechanical planarization processes. Pad conditioners are available in multiple sizes and configurations to fit most new and legacy CMP tools.

Semiconductor Manufacturing Industry Product Categories

-

Adhesives for Temporary Wafer Bonding

Adhesives for Temporary Wafer BondingEnabling faster, easier, more reliable ways to build tomorrow's semiconductors. 3M Wafer Support System (WSS) is proven in high‐volume manufacturing for temporary wafer bonding during wafer thinning and additional TSV processes.

-

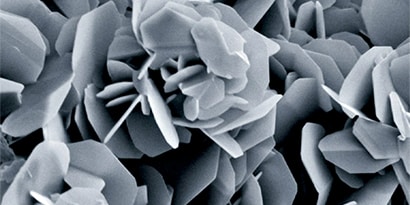

Boron Nitride Cooling Fillers

Boron Nitride Cooling FillersThese micro-structured additives improve the “cool factor” of electronics by helping conduct and dissipate heat in chip components.

-

CMP and Surface Finishing Materials

CMP and Surface Finishing Materials3M CMP and surface finishing materials can help increase productivity, improve yields and provide high-quality process performance.

-

Tape and Reel

Tape and ReelHelp protect your components during shipping and storage to meet your requirements and increase productivity.

-

Test and Burn-In Sockets

Test and Burn-In SocketsThe versatile product design helps enable reliable performance for test and burn-in applications.

Selecting the Right Semiconductor Product for Your Application

Have questions or need help finding the right semiconductor product? Simply click on the button to contact us and send us a message.